ABOUT ENSI

Since its establishment, ENSI has been committed to the development and application of new envelope materials suchas radiant barrier, vapor barrier, waterproof,vaportransmission, corrosion resistance,anti-UV aging barriermaterial and membranes. The company has a professionaland efficient R&D and testing center and an advancedproduct manufacturing base, which can independentlydevelop special membranes required by the market.

DATA DOWNLOAD

NEWS

SOLUTIONS

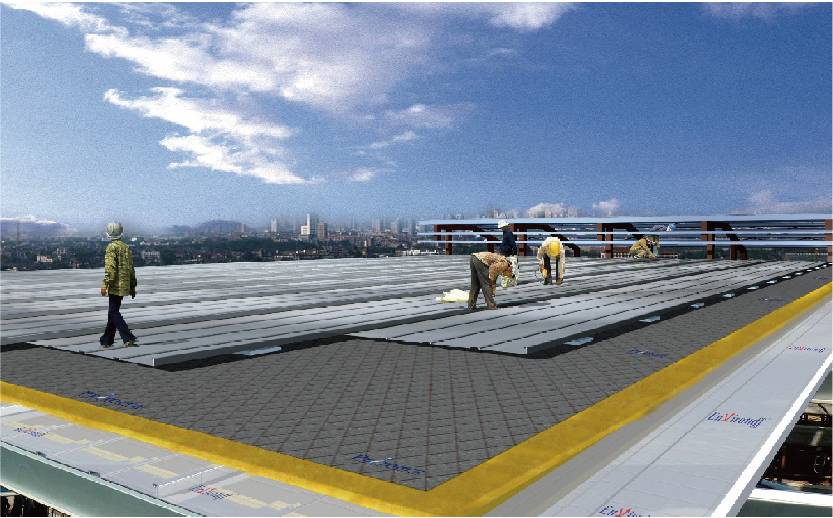

Ensi is committed to the development and application of roof and wall maintenance systems. According to different climatic regions and buildings with different structures, different application schemes are proposed for different requirements of thermal insulation, waterproof and moisture-proof...

INDUSTRY CASE

INDUSTRY CASE

CONTACT US

Shanghai Company

-

Address:Room 503.building 1.No.139 Hengxi Road,Minhang District,Shanghai

Tel:+86-21-51699397

Fax:+86-21-51507176

Email:info@ensi.com.cn

Beijing Branch

-

Address:902B, Floor 9, Tower A, Guanghua Building,

No. 8 Guanghua Road, Chaoyang District, Beijing

Tel:010-56217780

Fax:010-85800558

CopyRight © 2022 ensi.com.cn. All Rights Reserved.SHANGHAI ENSI INDUSTRIAL CO., LTD.沪ICP备06056848号